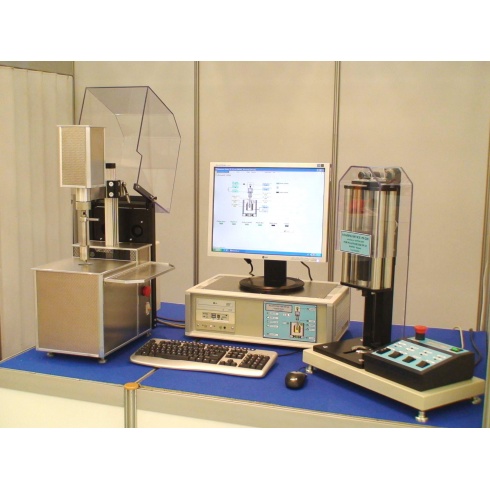

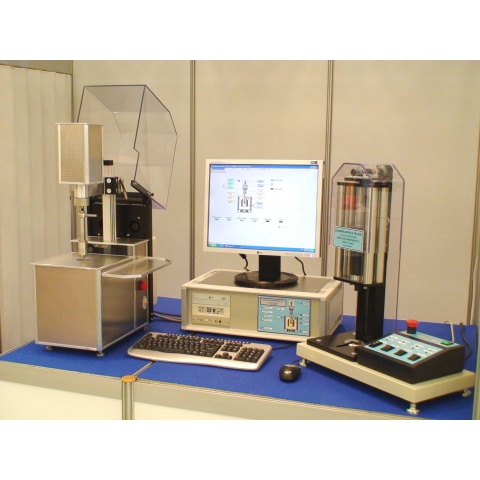

PF-22 Plastometer

Plastic properties of the tested coal are determined using a constant torque stirrer placed in the retort with the sample of coal (or coal mixture). The retort is heated in a salt (or Sn/Pb metal) bath in an electric resistance furnace.

During the test, temperature of the coal batch increases in a defined manner, while its softening (even melting) occurs in certain temperature range. This state is identified and quantified through stirrer's rotation, where the current rotational speed corresponds with current plasticity (fluidity) of the coal sample.

This method provides a semi-quantitative assessment of the plastic properties of coal batch used for coking. The aim is to simulate as true as possible the real conditions of the industrial coking process.