RF-33/TV/RDI

The RF-33/TV/RDI System is the latest and most comprehensive version of the original RF-33 System for coke quality testing. The RF-33/TV/RDI has been designed primarily to test the properties of the iron ore charge – lump ores, pellets, and sinter. However, in case of adding the coke making software modules and CSR testing equipment, it is also possible to test coke properties alike with the RF-33, RF-33/KK or RF-33/TV Systems. The RF-33/TV/ RDI System therefore can be, generally said, widely usable for studying high-temperature physicochemical properties of metallurgical raw materials in the environment of process gases.

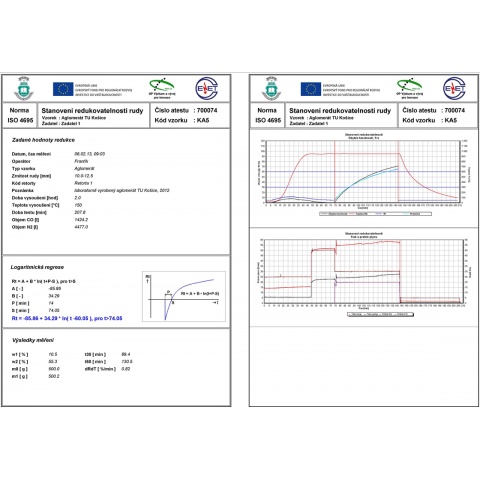

Testing of the iron-containing charge materials can be performed according to the relevant Standards (ISO 4695, ISO 7215, ISO 4696-1, and ISO 4696-2), or, for research purposes, also by some non-standard procedures.