DGS-OS/3D diagnostic system

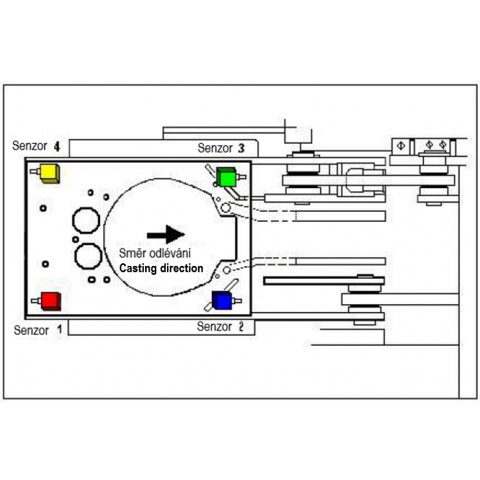

The primary function of DGS-OS/3D system is to diagnose the mechanical state of the oscillating mechanism of the mould assembly. The evaluation is based on 3D analysis of the oscillating table motion, which is scanned using four three-axis acceleration sensors mounted at the corners of the table. From the analysis of these signals, it is then possible to precisely assess the mechanical state of the oscillation mechanism. The information obtained can be used in particular for the needs of early maintenance of the equipment and thus for prevention of malfunctions, and, as well as for right adjustment of oscillations from the point of view of metallurgical parameters of casting.

The second basic function of the system is to indicate formation of a rupture in the cast strand shell, and to give warning before possible break-out occurrence. This function is based on two complementary principles, namely on indirect determination of the frictional forces in the mould, and on measurement of temperatures in the mould walls by means of special thermocouple probes. Indirect determination of friction forces in real time of casting is based on specialized analyses of the character of mould oscillations.