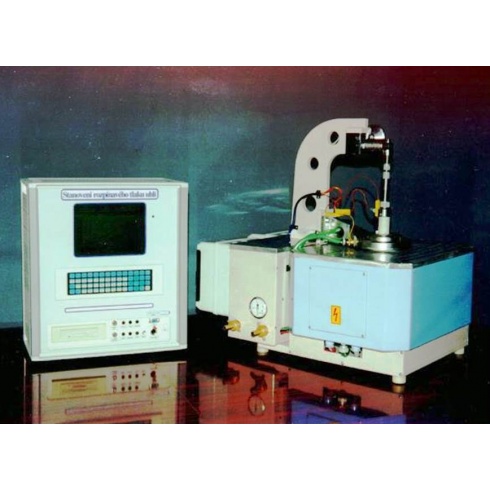

MRS-1 Device for Measuring of Expansion Pressure

One of the most important phenomena occurring in coke ovens during the coking process is the expansion pressure. The coal charge softens during the carbonization process and its volume increases, resulting in generation of pressure directed towards the heating walls of the chamber.

Different types of coal used for coking are characterized by different intensity of this phenomenon. Although high expansion pressure has a positive effect regarding the coke quality, the risk of damaging the walls of the coke oven chamber or even destroying it must be taken into consideration.

Several methods of measuring and predicting the value of expansion pressure are known which use direct and indirect measurements. Unlike determining other parameters, no internationally accepted ASTM and ISO standards exist for the measurement of expansion pressure at present.